Corrosion is a problem. QTA’s Permanent Solution is the only answer.

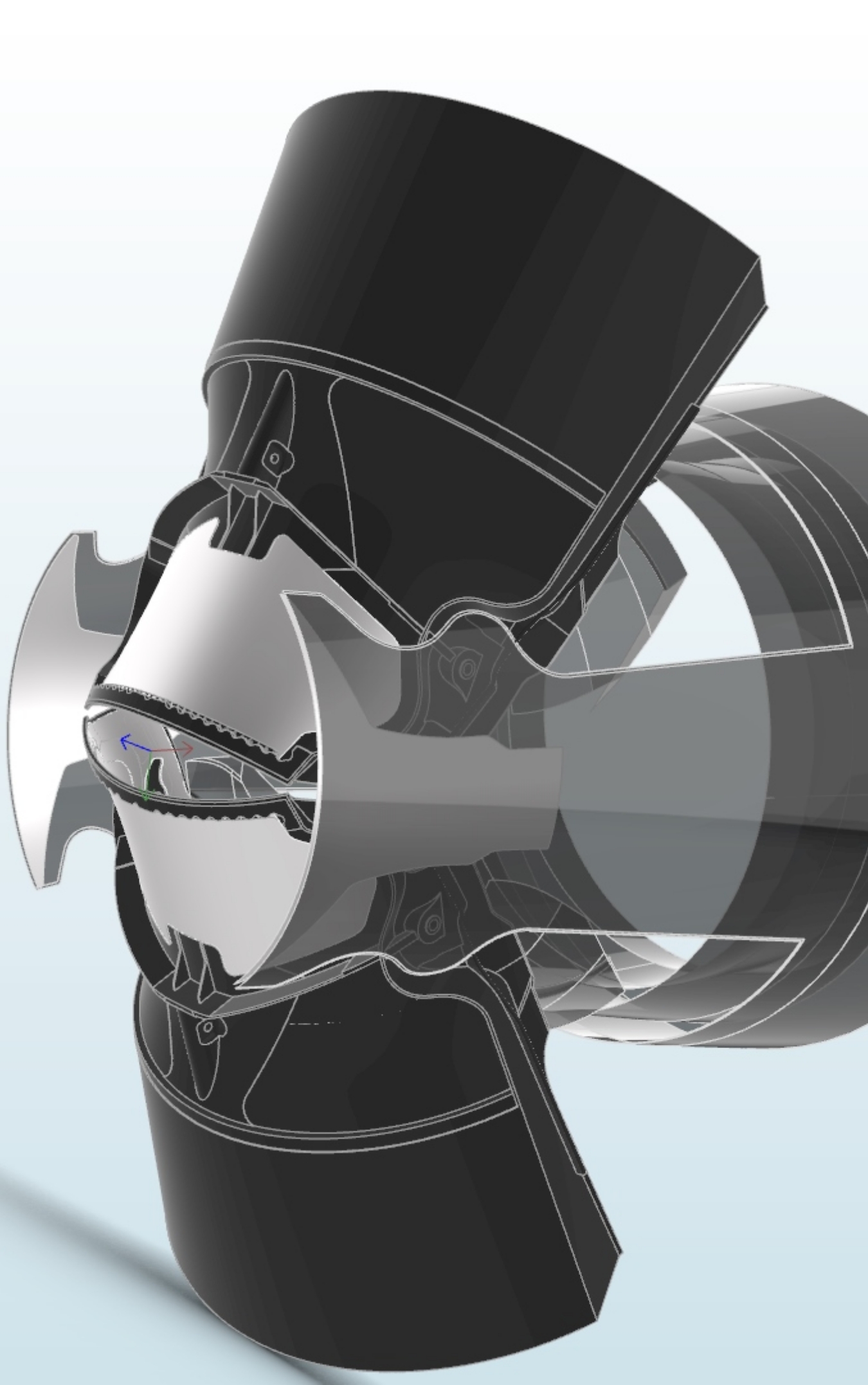

There is a significant and recurring corrosion problem with Thrust Reverser Doors and Side Beam assemblies on Honeywell HTF7000 engines. Until now, an operator’s only remedy was to replace a TR Door with factory New and if the Side Beams are out of limit a new assemble, both at tremendous cost.

QTA has engineered a Permanent Solution that re-manufactures the door, replacing the aluminum in the corroded area with new Titanium parts. The Side Beams are protected by a new Titanium cap.

Thrust Reversers installed on the Honeywell HTF7000 engine are used on four different Super Mid Size business jets

- Bombardier Challenger 300/350

- Gulfstream G280

- Embraer Legacy 450/500 (including the Praetor 500/600)

- Textron Longitude.

In service experience shows the aft portion of the Thrust Reverser (TR) Doors and the Side Beam structure are suffering from corrosion. Attempts by the OEM to provide a solution have failed. Operators are left with the problem and TR doors become unserviceable once corrosion exceeds OEM limits.

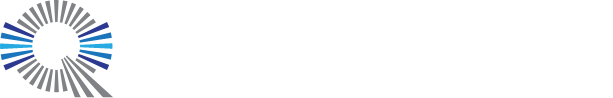

QTA analysis and research revealed the root cause of the corrosion is impingement of the jet exhaust, in line with the lobes of the internal exhaust mixer nozzle, on the aft surfaces of the TR doors and Side Beams.

This high velocity, elevated temperature, gas flow causes “Jet Erosion Corrosion” which breaks down the molecular structure of the 2219 aluminum that the TR Doors and Side Beam are manufactured. The surface becomes more susceptible to corrosion and adding the bi-products of combustion; Carbon, Sulphur and Nitrous Oxide which combined with moisture give a corrosive coating, and pitting corrosion results.

The Permanent Solution

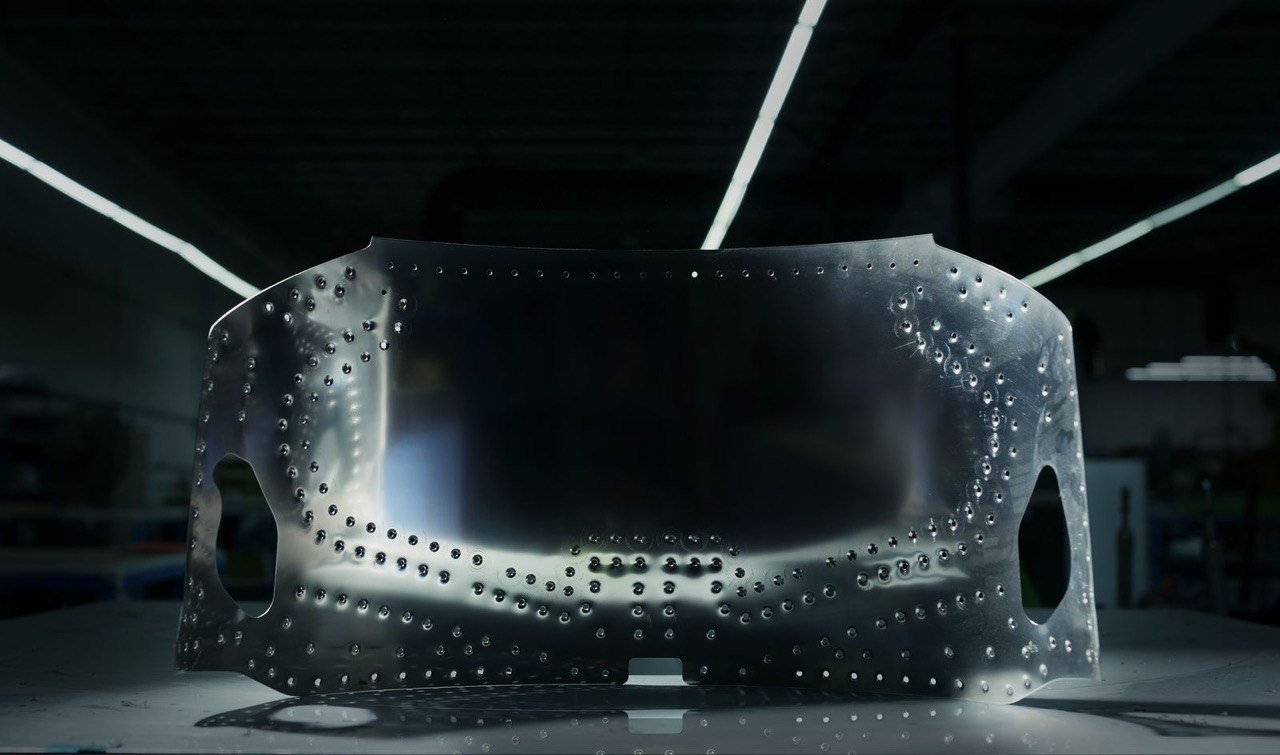

The QTA Permanent Solution is unique in re-manufacturing the original doors, a one piece forging in 2219, replacing the aluminum in the corroded area with new Titanium parts. The Side Beams are protected by a new Titanium cap.

Titanium has been used in Thrust Reverser assembles for many years. It is a proven material that guards against corrosion.

The new QTA Titanium parts are hot formed in CP70 titanium.

Attachment of the new Titanium part to the existing structure is conventional using Hi-Loks. The internal contour and exit area of the TR is kept exactly as the original so there is no impact on engine performance.

For the Side Beams, a thin Titanium “skin” is mechanically fastened to the surface and provides protection of the aluminum structure from the jet exhaust.

QTA has fully engineered every detail of the TR assembly to accept its parts and never fail.

A key feature of the QTA upgrade is that QTA can take a TR Door that has corrosion beyond the OEM limits and remanufacture it to the upgraded standard. The same is also true for the Side Beams.

Lifetime Structural Warranty

Lifetime means Lifetime

Your upgraded QTA Permanent Solution Thrust Reverser Doors and Side Beam assembles are backed by a lifetime structural warranty, which is assigned to the aircraft serial number.

- A QTA warranty remains with the aircraft serial number and is fully transferable throughout the airplane’s life.

- Backed by Product Liability Insurance formed and placed by Lloyd’s of London. You’re covered – For Life.

Applicability

The HTF7000 engine is currently in operation on several Super Mid Size Jets

- Bombardier Challenger 300 and 350

- Gulfstream G280

- Embraer Legacy 450/500 series and Embraer Praetor 500/600

- Textron Citation Longitude

UPGRADE YOUR TR’s - FOR LIFE

Avoid expensive MSP+ Service Programs that don’t provide a solution, just recurring expense.

Eliminate the MAPAERO expense and aircraft downtime.

- Get the Permanent SOLUTION at a fraction of the cost of the OEM option,